China OEM Stainless Steel Manifold - Downhole Motors’ Detail Features – LUQI

China OEM Stainless Steel Manifold - Downhole Motors’ Detail Features – LUQI Detail:

Detail Features & Advantages

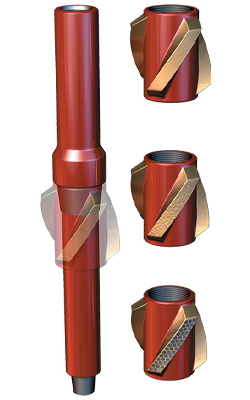

1. Adjustable Bend Housing

In drilling the non-conventional wells such as directional wells, horizontal wells, and highly-deviated wells, downhole motor with adjustable bend housing which uses the new coupling design can be adjusted from 0°to 4°at 19 different angles. It overcomes the shortcomings of flat universal shaft such as the exposed surfaces are susceptible to erosion and short operational life.

2. New Drive Seal Universal Shaft

The new drive seal universal shaft effectively increases the contact area of transmission components and reduces their contact stress. It helps to increase carrying capacity and service life of the universal shaft.

3. Uniform Wall Thickness Downhole motor

Through changing the shape of stator housing in a reasonable way, it makes stator’s rubber thin and uniform which overcomes the shortcomings of conventional stator technology. The downhole motor with even wall stator has advantages such as high cooling efficiency, rubber thermal expansion, good even sealing effect , broader adaptation range, more optimized structure and lighter overall mass, all of which can improve the working environment and life of downhole motor.

4. High-temperature Motor

The resistant temperature of motor can achieve over 150′C by the using of excellent resistant temperature rubber in the stator. It can meet the requirement of the High temperature well, ultra deep-well.

5. Rotor Surface treatment

The special chrome method makes the layer thickness of the valley and peak same.

The tungsten carbide coating layer of rotor has stronger ability of corrosion and wear resistance, enabling the down-hole motor to work normally in the saturated saltwater mud.

6. Changeable Stabilizer

To meet the requirements of different drilling conditions, we equipped the housing of the drive shaft assembly with different types of stabilizers: Fixed and Changeable ones, etc. We can provide different kinds of stabilizers for customers to choose.

Product detail pictures:

Related Product Guide:

Directional well essential-Downhole Motor

We always follow the principle "Quality Very first, Prestige Supreme". We have been fully committed to delivering our customers with competitively priced high-quality products and solutions, prompt delivery and experienced services for China OEM Stainless Steel Manifold - Downhole Motors’ Detail Features – LUQI , The product will supply to all over the world, such as: Denmark, Frankfurt, Afghanistan, With the development of the society and economy, our company will continue the "loyalty, dedication, efficiency, innovation" spirit of enterprise, and we will always adhere to the management idea of "would rather lose gold, do not lose customers heart". We will serve the domestic and foreign businessmen with sincere dedication, and let us create bright future together with you!

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!