OEM Manufacturer Drilling Rig - Manifold – LUQI

OEM Manufacturer Drilling Rig - Manifold – LUQI Detail:

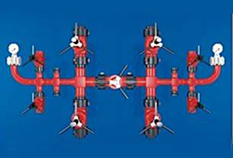

The drilling manifold an important equipment in Ou Gas) drilling circutation system. It pumps high-pressure mud into the well, clean well bottom, carries debris, and complete the drilling fluid circulation.

The drilling fluid manifold is composed of hard seal mud gate valves, high pressure spherical unions,high pressure gauges, short joints, etc.The ground manifold has features of compact structure and lower hydraulic resistance. The Rig floor manifold adopt reducing crosses, which is convenient of single standpipe/double standpipe.

Main Technical Parameters

|

Type |

ZG102-35 |

ZG102-53 |

ZG100-70 |

|

Working Pressure (MPa/psi) |

35/5000 |

52/7500 |

70/10000 |

|

Test Pressure (MPa/psi) |

53/7500 |

80/11250 |

105/15000 |

|

Normal l.D(mm) |

Φ102 |

Φ100 |

|

|

Working Temperature (℃) |

P-U:-29℃-+121℃; L-U:-46℃-+121℃ |

||

|

Connection |

Flexible joint(Union/4’’-1003、4’’-1002、2’’-1502 |

||

|

Working Media |

Mud,crude,oil,clean water,fracturing fluid,etc |

||

M series modular drilling fluid manifold is of high compressive strength,high safety ,long service lift and modular design and manufacture shorten time of installation and disassembly time.

Main Technical Features

1. The whole set of drilling fluid pipe assembly products are designed and manufactured according to the four modules of Derrick rise, drilling platform gate valve group, ground pipeline and ground gate valve, to realize modularization, to improve the efficiency of assembly of on-site pipes, and to shorten the installation.

2. The control gate valve adopts new design of anti-sand setting, flexlble switch and small torque, which solves the blockage of gate valve.

3. Pressure bearing parts made of high strength alloy and automatic welding, improve the strength and service life.

Main Technical Parameters

|

Type |

ZG102-35 |

ZG102-53 |

ZG100-70 |

|

Working Pressure (MPa/psi) |

35/5000 |

52/7500 |

70/10000 |

|

Test Pressure (MPa/psi) |

53/7500 |

80/11250 |

105/15000 |

|

Normal l.D(mm) |

Φ102 |

Φ100 |

|

|

Working Temperature (℃) |

P-U(-29℃-+121℃) |

||

|

Specification Class |

PSL3 |

||

|

Material Code |

EE |

||

|

Working Media |

Mud, crude, oil, clean water, fracturing fluid, etc |

||

|

Connection |

Flexible joint(Union/4″-1003, 4″-1002, 2″-1502 |

||

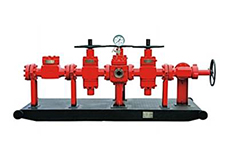

Choke Manifold

When drilling fluid in wellbore is polluted by stratigraphic liquid, will break the balance between the hydrostatic column pressure of drilling fluid and the pressure of stratigraphic liquid, resulting in overflow and blowout. When the blowout preventer is closed, the throttle valves’opening or closing can control the back pressure to maintain a certain bottom well pressure, so as to circulate out the polluted drilling fluid or pump in to new drilling fluid.

Main Technical Parameters

|

Working Temperature |

L, P, R, S, T, U, V |

|

Performance Requirement |

PR1-PR2 |

|

Specification Level |

PSL3-PSL4 |

|

Material Class |

EE, FF |

|

Working Pressure |

14-105MPa |

|

Material Code |

45K, 60K, 75K |

|

Working Medium |

Drilling fluid, crude oil, natural gas, etc. |

|

Applicable Environment |

EE, FF-Acid environment [Conform to the definitions in Sulfide resistant Stress Cracking Metal Material of Oilfield Equipment(MR0175)of National Association of Corrosion Engineers(NACE)] |

Kill Manifold

Main Technical Features

1. The choke manifold is applied to control overflow blowout and pressure of oil-gas wells.

2. When the wellbore is fully sealed by blind Ram, kill operation is carried out by forcibly pump heavy mud to the wellbore through kill manifold.

3. When blowout, fresh water shall be forcibly poured into the wellhead through kill manifold to prevent fire.

4. when a fire after blowout, fire extinguishing agent shall be forcibly poured into the wellbore through kill manifold to extinguish the fire.

Main Technical Parameters

|

Working Temperature |

L, P, R, S, T, U, V |

|

Performance Requirement |

PR1-PR2 |

|

Specification Level |

PSL3-PSL4 |

|

Material Class |

EE、FF |

|

Working Pressure |

14-105MPa |

|

Material Code |

45K, 60K, 75K |

|

Working Medium |

Drilling fluid, crude oil, natural gas, etc. |

|

Applicable Environment |

EE, FF-Acid environment [Conform to the definitions in Sulfide resistant Stress Cracking Metal Material of Oilfield Equipment(MR0175)of National Association of Corrosion Engineers(NACE)] |

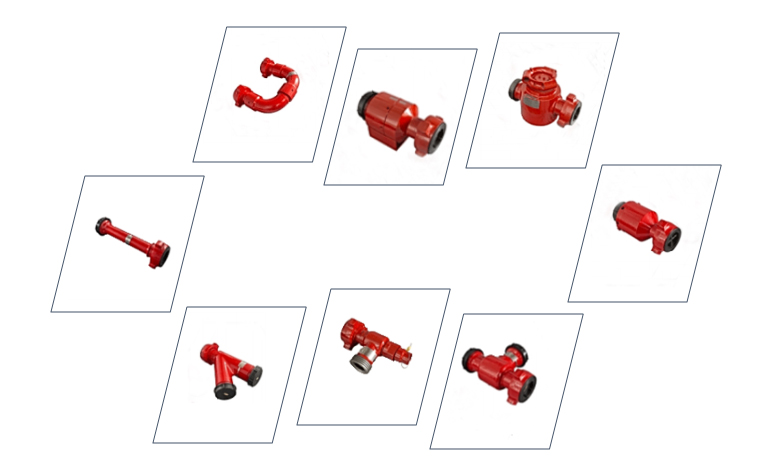

Fracturing Manifold

On the premise of ensuring mechanical properties, optimize critcal dimension and reduce the weight of the fracturing manifold; optimize material of body and increase the internal diameter of the fracturing manifold elements. Special process for elbow inner surface improves inner core strength and the outer core ductility; floating seal plug valve with split stem and cock makes reliable sealing and long service life.

Main Technical Features

The pipe are treated with self tightening technology to make the internal side of the pipe bears compression prevent the fatigue crack from expanding.

Increase the internal diameter of the pipe fittings to reduce weight and adapt to large displacement operation.

Lateral tees and T-tees are adopted with integral forging process to achieve high strength and long service life

The internal surface of lateral tees and T-tees adopt shot blasting technology, achieved higher anti-fatigue strengthening factor and surface anti-scour ability.

Chiksan adopt ladder roller path design, increase thickness and rotation flexibility of the hinged area.

Plug valve is designed with floating valve core bi-directional sealing, which makes balanced loading on sealing arcs and small torque.

The fracturing manifold is designed with eight annular inlets which reduces the volume of manifold assembly, and features convenient transportation and quick operation.

Main Performance Data

|

Temperature Class (℃) |

L-U(-46℃-121℃) |

|

Working Pressure(MPa) |

105, 104 |

|

Working Medium |

CO, N, Fracturing fluid, fracturing sand, liquid CO, N |

Product detail pictures:

Related Product Guide:

Design Theory of Stator and Rotor of PDM Based on Rack Gearing Principle

Directional well essential-Downhole Motor

We have our own product sales staff, style crew, technical group, QC staff and package staff. We now have strict high quality management procedures for each approach. Also, all of our workers are experienced in printing subject for OEM Manufacturer Drilling Rig - Manifold – LUQI , The product will supply to all over the world, such as: Leicester, Botswana, Marseille, During the short years, we serve our clients honestly as Quality First, Integrity Prime, Delivery Timely, which has earned us an outstanding reputation and an impressive client care portfolio. Looking forward to working with you Now!

The company leader recept us warmly, through a meticulous and thorough discussion, we signed a purchase order. Hope to cooperate smoothly