OEM manufacturer Used Oil Well Drilling Bits - Introduction of Downhole Motor – LUQI

OEM manufacturer Used Oil Well Drilling Bits - Introduction of Downhole Motor – LUQI Detail:

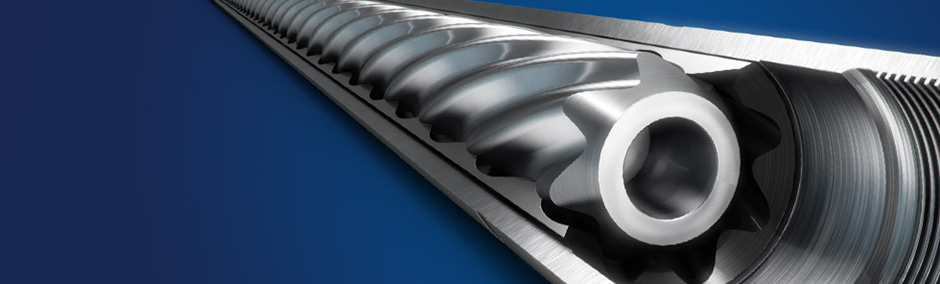

Introduction of Downhole motor/Mud motor

Down-hole motor/Mud motor is a positive-displacement motor(PDM), the high drilling fluid enters into the high fluid power converted into mechanical energy, and the rotor drives the principal shaft and bit rotating. We provide the Down-hole motor/Mud motor with diameter from 45mm to 286mm, vertical, single-bend, double-bend and adjustable motors; the hear-resistance temperature ranges are ≤120℃,120-150℃; oil-based mud resistance and saturated saltwater mud resistance motors. And we also design and manufacture according to customers’ special requirements:

1. Bent Down-hole motor: The bent angle on the universal axis can fit curvature of kicking off, Single-bent and double-bent are available.

2. Bent angle adjustable down-hole motor: The bent angle of the down-hole motor can be adjusted on well surface,which enhances the extension of the kicking off.

3. Extended down-hole motor: On the basis of the common downhole, motor, the torque can be increased with the step increasing for the motor.the bit drilling quickly.

4. Hollow rotor down-hole motor The adoption hollow rotor for different sizes of hard alloy jet nozzle the inputting flux and horsepower of drill bit.

5. High kick-off down-hole motor: The curvature of kicking-off can achieve l°/m with the particular design.the shortness length of the whole and adjacent adjacent bend to the bit.

6. Saturated saltwater mud resistant down-hole motor The special coating layer of rotor has stronger ability of corrosion and wear resistance. enabilng the down-hole motor to work for a long time in saturated saltwater mud.

7. High temperature down-hole motor The resistant temperature of motor can achieve over 150°C by the using of excellent resistant temperature rubber in the stator. With the ability of the resistant temperature rubber in the stator, the requirement of the deep-well.up deep-well and high temperature grads areas drilling can be satisfied.

8. Sealed transmission shaft down-hole motor:Converting the mud sealed to the oil sealed of transmission shaft,this improves the condition of thrust axletree and radial axletree, make the whole down-hole motor life long.

Product detail pictures:

Related Product Guide:

Design Theory of Stator and Rotor of PDM Based on Rack Gearing Principle

High-quality comes 1st; assistance is foremost; business enterprise is cooperation" is our business enterprise philosophy which is constantly observed and pursued by our business for OEM manufacturer Used Oil Well Drilling Bits - Introduction of Downhole Motor – LUQI , The product will supply to all over the world, such as: Qatar, Belgium, Slovenia, We warmly welcome your patronage and will serve our clients both at home and abroad with products of superior quality and excellent service geared to the trend of further development as always. We believe you will benefit from our professionalism soon.

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!